Gold-Beans Factory

Qingdao Jinxiu Liangyuan Textile Co., Ltd. was established on May 15, 2015, and is a subsidiary of Qingdao Jindou Household Products Co., Ltd. The company is located in Gongjiazhuang Industrial Park, Puji Town, Jiaozhou City, Qingdao. It covers an area of 6000 square meters. It mainly produces home textile products such as mattresses, pillows, quilt covers, quilts, blankets, etc. The factory is fully equipped, with 121 sets of sewing equipment, quilting equipment, cotton filling, carding equipment, needle inspection equipment, etc. With 76 employees and a total annual output of more than 2.5 million pieces.

Since its establishment, the company has been working hard to provide customers with high-quality products, improving quality from both hardware and software. Each production link strictly implements a standardized 5S management system. The high-precision equipment combined with the rich experience of technicians makes the products more compatible. And meet customer needs.

Factory Strengthens 5S Management

SEITON / Organize

Distinguish the essentials, keep the needs

SEIRI / Neatness

Necessities should be marked and placed clearly

SEISO / Cleaning

Remove dirt and keep it clean, improve the yield

SEIKETSU / Standardization

Consistent management to ensure order quality

SHITSUKE / Literacy

Qualified employees can take products seriously

Quality Assurance Details

1. Cutting

1)The cutting tool is calibrated once a year, and the error MPE: ±(0.03+0.02L) mm.

2)Color deviation management, colorfastness detection.

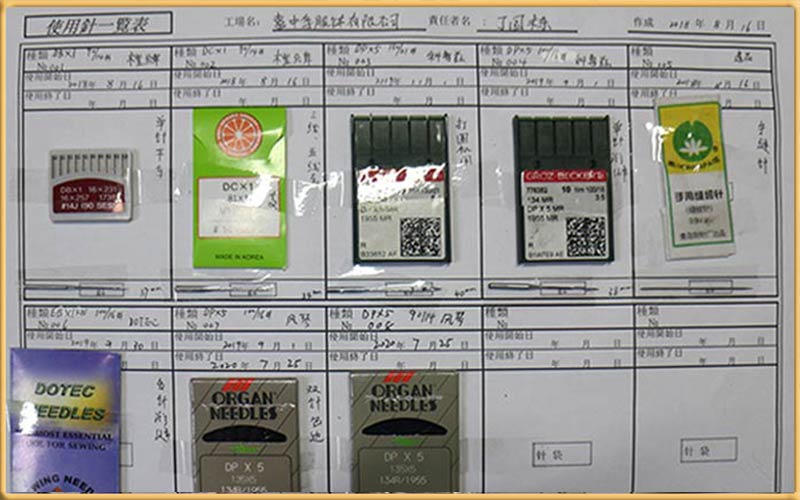

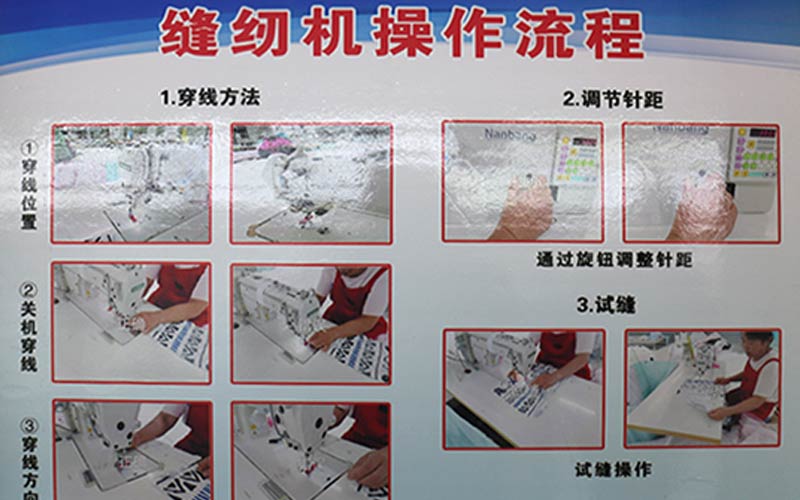

2. Sewing

1) Debug the equipment before production.

2) Inspection of semi-finished products during sewing.

3) Needle entry and exit management and broken needle management.

3. Cotton carding

Carry out cleaning, maintenance and debugging on the middle cotton carding machine.

4. Quilting

Pre-production commissioning, cleaning and maintenance of quilting equipment.

5. Inspection

1) Inspection area is divided into uninspected area, A area, and B area.

2) Inspection tools are calibrated once a year.

The tape measure is calibrated once a month and the error is within 0.5 mm.

6. Needle Ddetection

Clean and maintain the needle detector and produce daily reports on the needle detector’s operation and daily commentaries on the needle detector.

7. Package

Carry out meticulous product packaging before delivery, record the receipt and delivery of packaging accessories, and inspect the appearance of the packaging.

8. Warehousing

1) Carry out strict registration of warehouse entry and exit personnel

2) The goods are sorted and stacked on plastic pallets, and the goods are rigorously landed.